Impacts of the COVID-19 Pandemic on Supply Chains of the German Automotive Industry

Main Article Content

บทคัดย่อ

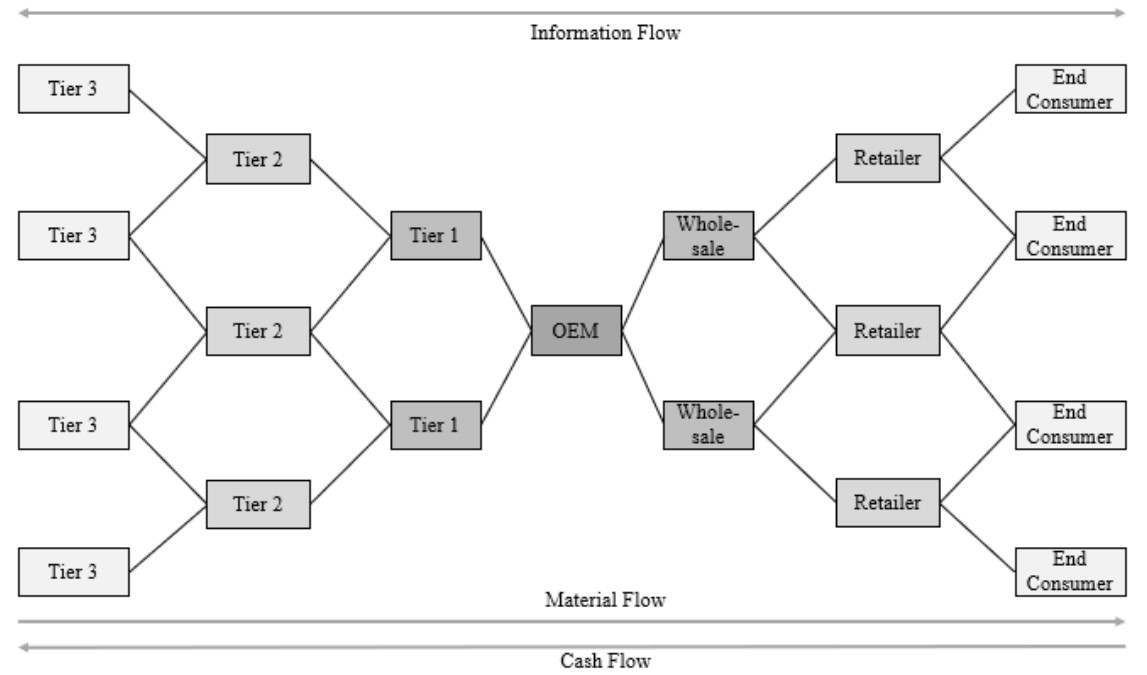

The COVID-19 pandemic has dramatically changed our daily lives in a very short time. International supply chains, such as those of the German automotive industry, have experienced major disruptions. Measures such as border closures or production stops caused these supply chains to collapse due to increasing globalization on both on supply and demand side and the associated dependency on the global flows of goods. This in turn has led to bottlenecks, fluctuations in demand as well as delays along the entire value chain. The aim of this paper is to illustrate the impacts of the COVID-19 pandemic along the supply chains of the German automotive industry. Based on the literature review, potentials were identified to be able to react more effectively against crises in the future. The solution of previous thesis, various articles of management consultancies and statements of German car manufacturers were consulted. The obvious impact of the COVID-19 pandemic could be seen in the border closures and government measures such as home office obligations and lack of materials. There was a drop in demand in the automotive sector due to a limited processing time. Significantly, fewer vehicles were produced, and companies had to deal with immense drops in sales. The theoretical findings identified four major factors that influence the disruption of supply chains. These include complexity, communication, risk management and geopolitical factors. Due to the low vertical integration of the German automotive industry and the resulting high dependency on suppliers, the optimization of these factors is essential in order to react better to crises in the future. A fundamental step could be the digitalization of supply chains and the transparency of communication between all parties. Furthermore, adjustment of inventories and procurement at national level should be taken into consideration for the disruption of supply chains in the future.

Article Details

อนุญาตภายใต้เงื่อนไข Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

บทความนี้ได้รับการเผยแพร่ภายใต้สัญญาอนุญาต Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International (CC BY-NC-ND 4.0) ซึ่งอนุญาตให้ผู้อื่นสามารถแชร์บทความได้โดยให้เครดิตผู้เขียนและห้ามนำไปใช้เพื่อการค้าหรือดัดแปลง หากต้องการใช้งานซ้ำในลักษณะอื่น ๆ หรือการเผยแพร่ซ้ำ จำเป็นต้องได้รับอนุญาตจากวารสารเอกสารอ้างอิง

Autozeitung (2021). Coronavirus: Auswirkungen auf die Autobranche. Retrieved November 5, 2021, from https://www.autozeitung.de/coronavirus-auswirkungen-auf-autobranche-automobilindustrie-198071.html.

Baumgarten, H (2004). Supply Chain Steuerung und Services: Entwicklungsphasen des Supply Chain Managements. Heidelberg: Springer.

Barter, J. K. L. (2020). COVID-19 Managing supply chain risk and disruption. Retrieved October 22, 2021, from https://www2.deloitte.com/global/en/pages/risk/articles/covid-19-managing-supply-chain-risk-and-disruption.html.

Böhnlein, C-B. (2005). Supply Chain Management, Das Wirtschaftsstudium 34, 1, 92-96.

BMWi (2021): Automobilindustrie. Retrieved October 19, 2021, from https://www.bmwi.de/Redaktion/DE/ Textsammlungen/ Branchenfokus/Industrie/branchenfokus-automobilindustrie.html.

Casey, M. J., & Wong, P. (2017). Global supply chains are about to get better, thanks to blockchain. Harvard Business Review, 13, 1-6.

Chowdhury, M. M. H., Agarwal, R., & Quaddus, M. (2019). Dynamic capabilities for meeting stakeholders' sustainability requirements in supply chain. Journal of Cleaner Production, 215, 34-45.

Corsten, H., & Gössinger, R. (2001). Einführung in das Supply Chain Management. München: Oldenbourg.

Deloitte (2020). Auswirkungen von COVID-19 Supply Chain Management: Auswirkungen von Krisen auf die Wertschöpfungskette. Retrieved September 24, 2021, from https://www2.deloitte.com/ content/ dam/Deloitte/at/Documents/Tax/transfer-pricing/auswirkungen-covid-19-supply-chain-management.pdf.

Eßig, M. (2020). RISIKEN IN DER LIEFERKETTE – CORONA BEEINFLUSST DEN WARENAUS-TAUSCH. Retrieved October 1, 2021, from https://www.unibw.de/home /news-rund-um corona/ die-risiken-in-der-lieferkette.

Geimer, H. (2005). Komplexitätsmanagement globaler Supply Chains. HMD Praxis der Wirtschaftsinformatik 42, 6, 38-46.

Göpfert, I. (2004). Integriertes Supply Chain Management. Theorie und Praxis effektiver unternehmens-übergreifender Geschäftsprozesse: Einführung, Abgrenzung und Weiterentwicklung des Supply Chain Managements. Wiesbaden: Gabler.

GTAI (2021). Beschaffungsmärkte der deutschen Automobilindustrie. Retrieved September 24, 2021, from https://www.gtai.de/gtai-de/trade/specials/special/eu/ beschaffungsmaerkte-der-deutschen-automobilindustrie-619998.

Hieronimus, M (2006). Strategisches Controlling von Supply Chains: Entwicklung eines ganzheitlichen Ansatzes unter Einbeziehung der Wertschöpfungspartner. Göttingen: Cuvillier.

Humphrey, J., & Lechowski, G. (2020). Lieferschock, Nachfragekrise, Technologiewandel Die Pandemie kann die europäische Autoindustrie nachhaltig verändern. WZB Mitteilungen, 168, 60-62.

Ivanov, D., & Sokolov, B. (2013). Control and system-theoretic identification of the supply chain dynamics domain for planning, analysis and adaptation of performance under uncertainty. European Journal of Operational Research, 224(2), 313-323.

Janßen, J., Kraut, A., Linnartz, M., Marek, S., Pause, D., & Schröer, T. (2020). Krisenbewältigung durch effizientes Supply-Chain-Risikomanagement. In vier Schritten turbulente Zeiten im SCM meistern. Position paper. FIR e. V. an der RWTH Aachen.

Kaleta, P. (2021). Goldener Handschlag: Mehr als 3.500 Daimler-Mitarbeiter haben Abfindungen von bis zu 400.000 Euro angenommen. Retrieved October 19, 2021, from https://www.businessinsider.de/ wirtschaft/mobility/goldener-handschlag-mehr-als-3-500-daimler-mitarbeiter-haben-abfindungen-von-bis-zu-400-000-euro-angenommen-r5/.

Keller, S., & Krol, B. (2004). Der Bullwhip-Effekt in Supply. Wirtschaftswissenschaftliches Studium 33, 2, 109-112.

Kloth, M. (1999). Effektives Supply Chain Management auf Basis von Standardprozessen und Kennzahlen: Instrumente des Supply Chain Managements in der Praxis. Dortmund: Praxiswissen.

Kolev, G., & Obst, T. (2020). Die Abhängigkeit der deutschen Wirtschaft von internationalen Lieferketten. IW-Report, 16, Institut der deutschen Wirtschaft: Köln.

Köllner, C. (2020). So wirkt sich die Corona-Krise auf die Automobilindustrie aus. Retrieved November 2, 2021, from https://www.springerprofessional.de/automobilproduktion/corona-krise/so-wirkt-sich-die-corona-krise-auf-die-automobilindustrie-aus/17831442.

Kords, M. (2020). Anzahl aufgrund von Corona-Maßnahmen nicht produzierter Kraftfahrzeuge in der europäischen Automobilindustrie nach Ländern. Retrieved November 5, 2021, from https://de.statista.com/statistik/daten/studie/1114156/umfrage/produktionsverlust-in-der-europaeischen-autoindustrie-durch-corona-nach-laendern/

Kords, M. (2021a). Größte Automobilhersteller nach Fahrzeugabsatz in 2020. Retrieved October 19, 2021, from https://de.statista.com/statistik/daten/studie/173795/umfrage/automobilhersteller-nach-weltweitem-fahrzeugabsatz/.

Kords, M. (2021b). Export von Kraftfahrzeuge und Landfahrzeuge aus Deutschland nach Abnehmerland im Jahr 2020. Retrieved October 19, 2021, from https://de.statista.com/statistik/ daten/studie/200694/ umfrage/die-wichtigsten-abnehmerlaender-fuer-pkw-aus-deutschland/.

Kords, M. (2021c). Umsatz der Automobilindustrie in Deutschland von 2010 bis 2020. Retrieved November 5, 2021, from https://de.statista.com/statistik/daten/studie/160479/umfrage/umsatz-der-deutschen-automobilindustrie/.

Kugeler, M. (2002). Prozessmanagement: Ein Leitfaden zur prozessorientierten Organisationsgestaltung: SCM und CRM: Prozessmodellierung für Extended Enterprises. Berlin: Springer.

Kuhn, A., & Hellingrath, B. (2002). Supply Chain Management. Optimierte Zusammenarbeit in der Wert-schöpfungskette. Berlin: Springer.

Kropik, M. (2009). Produktionsleitsysteme in der Automobilfertigung. Heidelberg: Springer.

Kumar, S., & Managi, S. (2020). Does stringency of lockdown affect air quality? Evidence from Indian cities. Economics of Disasters and Climate Change, 4(3), 481-502.

McKinsey Global Institute. (2020). Risk, resilience, and rebalancing in global value chains. Retrieved November 11, 2021, from https://www.mckinsey.com/business-functions/operations/our-insights/risk-resilienceand-rebalancing-in-global-value-chains.

Manager Magazin (2020). BMW senkt Ausblick und will Stellen streichen. Retrieved October 19, 2021, from https://www.manager-magazin.de/unternehmen/autoindustrie/bmw-ag-will-stellen-streichen-a-1306768.html.

Mansfield-Devine, S. (2017). Beyond Bitcoin: using blockchain technology to provide assurance in the commercial world. Computer Fraud & Security, 2017(5), 14-18.

Mazareanu, E. (2021). How has COVID-19 negatively impacted your supply chain?. Retrieved November 2, 2021, from https://www.statista.com/statistics/1182233/impact-covid-19-supply-chain/.

Melzer-Ridinger, R. (2005). Das Konzept Supply Chain Management, HMD Praxis der Wirtschaftsinformatik 42, 6, 7-16.

Oloruntoba, S. R. (2020). The "New Normal": Rethinking Supply Chains during and after COVID-19 Global, Business Environment. International Journal of Physical Distribution & Logistics Management. Retrieved October 22, 2021, from https://www.emeraldgrouppublishing.com/journal/ijpdlm/new-normal-rethinking-supply-chains-during-and-after-covid-19-global-business.

Parsons, T. (2020). How Coronavirus Will Affect the Global Supply Chain. Retrieved October 22, 2021, from https://hub.jhu.edu/2020/03/06/covid-19-coronavirus-impacts-global-supply-chain/.

Pató, G. S. B., & Herczeg, M. (2020). THE EFFECT OF THE COVID-19 ON THE AUTOMOTIVE SUPPLY CHAINS. Studia Universitatis Babes Bolyai – Oeconomica, 2, 1-11.

Pedersen, F., & Nylænder, L. C. (2021). The Impact of COVID-19 on Global Supply Chains (Master’s thesis). University of South-Eastern Norway, Norway.

Pfohl, H-C. (2004). Logistiksysteme. Betriebswirtschaftliche Grundlagen. Berlin Heidelberg: Springer.

Porter, M. E. (1985). Competitive advantage: Creating and sustaining superior Performance. New York: Free Press.

Proff, H. (2020). COVID-19 Briefing: "Die Route wird neu berechnet", Die Corona-Krise und die Automobilindustrie, Retrieved November 11, 2021, from https://www2.deloitte.com/de/de/blog/covid-19-briefings/2020/covid-19-briefing-krise-automobilindustrie.html.

Reichert, K. (2020). Die 5 umsatzstärksten Branchen in Deutschland. Retrieved September 30, 2021, from https://www.ig.com/de/trading-strategien/umsatzstaerkste-branchen-in-deutschland-190312

Sattler, S. (2020). Wie Daimler mit der COVID-19-Pandemie umgeht. Retrieved October 20, 2021, from https://www.daimler.com/magazin/berufsleben/daimler-und-corona.html#anchor_1177854.

Sydow, J. (2002). Zum Management von Logistiknetzwerken. Logistik Management, 4(2), 9-15.

Taleb, N. N. (2012). Whatever the wearther. Financial Times. Retrieved November 2, 2021, from https://www.ft.com/contenta49f8514-3329-11e2-8e44-00144feabdc0.

VDA (2007). Jahresbericht. Eisenach: Verband der Automobilindustrie.

VDA (2021). Europäischer Pkw-Markt bricht 2020 um ein Viertel ein. Retrieved November 5, 2021, from https://www.vda.de/vda/de/presse/Pressemeldungen/210119-Europ-ischer-Pkw-Markt-bricht-2020-um-ein-Viertel-ein.

VDA (2020a). Corona-Krise sorgt im ersten Halbjahr 2020 für beispiellosen Einbruch auf den internationalen Pkw-Märkten. Retrieved October 1, 2021, from https://www. vda.de/de/presse/Pressemeldungen/ 200716-Corona-Krise-sorgt-im-ersten-Halbjahr-2020-f-r-beispiellosen-Einbruch-auf-den-internationalen-Pkw-Maerkten.html.

VDA (2020b). VDA erwartet für 2020 rund ein Viertel weniger Pkw-Verkäufe in Deutschland und Europa. Retrieved October 1, 2021, from https://www.vda.de/vda/de/presse/Pressemeldungen/200703-VDA-erwartet-f-r-2020-rund-ein-Viertel-weniger-Pkw-Verk-ufe-in-Deutschland-und-Europa.

Volswagen (2020). Volkswagen Group measures reduce the effects of Covid-19 in the first half of the year. Retrieved November 11, 2021, from https://www.volkswagenag.com/en/news/2020/07/2020-H1.html#.

Volkswagen AG (2021). Personal und Organisation. Retrieved October 19, 2021, from https:// www.volkswagen-newsroom.com/de/personal-und-organisation-3694.

Wallentowitz, H., Freialdenhoven, A., & Olschewski, I. (2009). Strategien in der Automobilindustrie. Technologietrends und Marktentwicklungen. Wiesbaden: Vieweg + Teubner.

Werner, B., & Thorn, J. (2003). Collaborative Supply Chain Planning. Wirtschaftswissenschaftliches Studium 32, 10, 590-595.

Werner, H (2004). Supply Chain Management. Grundlagen, Strategien, Instrumente und Controlling. Berlin & Heidelberg: Springer.

Zhu, G., Chou, M. C., & Tsai, C. W. (2020). Lessons Learned from the COVID-19 Pandemic Exposing the Shortcomings of Current Supply Chain Operations: A Long-Term Prescriptive Offering. Sustainability, 12(14), 5858.