Applying Lean and Six Sigma Concept to Reduce Inventory Cost of SME in Thailand After Covid-19 Crisis : A Case Study of Takara Planning Company Limited

Main Article Content

บทคัดย่อ

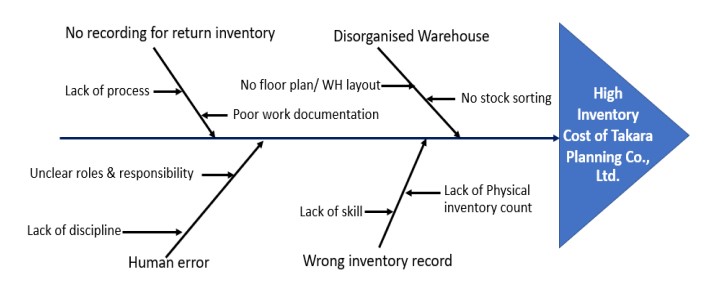

Takara Planning Co., Ltd. is an SME running the business of re-packaging and shipping the balloons product for the customers in Japan. During COVID-19 lock down crisis, the company faced the problem of high inventory holding costs due to products returned, disorganised warehouse, improper inventory control, and increasing of inventory holding costs, especially the cost of warehouse space rental that tend to keep increasing. The objective of this research is to 1. examine the cause of problems in the work process of the warehouse which impact the inventory cost, and 2. reduce the inventory cost of the company. The tools used in the study were the concept of Lean Six Sigma (DMAIC), Cause and Effect Diagram, 5S and ECRS principles. The result showed that applying Lean Six Sigma concept and the tools (DMAIC, 5S, ECRS) to lean waste in the warehouse reduced the warehouse space occupancy from 92% to 62%. It means we gained available space back 26% by the improvement. In terms of cost, after improvement, we reduce the warehouse space rental cost from 8,140,000 Baht to 5,816,400 Baht. It showed that the improvement by applying Lean Six Sigma and tools (DMAIC, 5S, ECRS) reduced the inventory cost of by 2,323,600 Baht for Takara Planning Co., Ltd.

Article Details

อนุญาตภายใต้เงื่อนไข Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

บทความนี้ได้รับการเผยแพร่ภายใต้สัญญาอนุญาต Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International (CC BY-NC-ND 4.0) ซึ่งอนุญาตให้ผู้อื่นสามารถแชร์บทความได้โดยให้เครดิตผู้เขียนและห้ามนำไปใช้เพื่อการค้าหรือดัดแปลง หากต้องการใช้งานซ้ำในลักษณะอื่น ๆ หรือการเผยแพร่ซ้ำ จำเป็นต้องได้รับอนุญาตจากวารสารเอกสารอ้างอิง

Dwivedi V. K., Islam, A. & Sharma, A. (2021). Application of 5s Methodology in a Small-Scale Enterprise: Case Study. Springer. https://doi.org/10.1007/978-981-16-3135- 1_4.

Hong, C. (2017). Implementing lean six sigma to achieve inventory control in supply chain management. In AIP Conference Proceedings. 3rd International Materials Industrial and Manufacturing Engineering Conference (MIMEC2017). DOI : 10.1063/1.5010654.

International Monetary Fund. (2020). World Economic Outlook Reports. 2020. Retrieved from https://www.imf.org/en/Publications/WEO/Issues/2020/04/14/weo-april-2020. Accessed on 17/Jun/2020.

Krajungduang, K., Singhdong, P. & Weerapong, P. (2021). Improving Warehouse Operations with Mobile Applications and ECRS Concepts Case Study of Yusen Logistics (Thailand) Co., Ltd. Journal of Learning Innovation and Technology (JLIT) Vol. 1, No. 2, July – December 2021.

Lande, M., Shrivastava, R. & Seth, D. (2016). Critical success factors for lean six sigma in SMEs (small and medium enterprises). The TQM Journal, 28, 613-635. https://doi.org/10.1108/TQM-12-2014-0107.

Murray, M. J. (2019). The Six Sigma Strategy's DMAIC Problem-Solving Method. Retrieved from https://www.thebalancesmb.com/six-sigma-concepts-the-dmaic-problem-solving-method-2221186.

Myerson, P. (2021). Lean supply chain and logistics management. McGraw-Hill. New York University Gallatin. Retrieved from https://gallatin.nyu.edu/academics/graduate/curriculum/independent/GGguidelines.html.

Office of SMEs Promotion (OSMEP). (2020). SMEs White Paper Report 2018. Bangkok: OSMEP.

Osada, T. (2017). The 5S's: Five keys to a Total Quality Environment. US: Asian Productivity Organization.

Rizkya, I., Sari, R., Syahputri, K., & Fadhilah, N. (2021). Implementation of 5S methodology in warehouse: A case study. IOP Conference Series: Materials Science and Engineering. 1122. 012063. 10.1088/1757-899X/1122/1/012063.

Salah, S. & Rahim, A. (2019). The Integration of Six Sigma and Lean: Combining Lean Six Sigma with Process Improvement in An Integrated Company-Wide Management System. Emerald. DOI: 10.1007/978-3-319-99034-7_4.

Smetkowska, M. & Mrugalska, B. (2018). Using six sigma DMAIC to improve the quality of the production process: a case study. Procedia Social and Behavioral Sciences, 238, 590-596. https://doi.org/10.1016/j.sbspro.2018.04.039.